EPS Foam Sandwich Wall Roof Panels

Foam core material is mainly foam plastic: the prominent feature of Foam Sandwich structure is large bending rigidity, light weight, material strength can be fully utilized. The performance of Foam Sandwich structure depends on panel material and foam core material, generally, the mechanical properties of Rigid Foam Sandwich structure are better than those of two-foam Sandwich structure. There are two main manufacturing methods: one is to prepare the foam core first and then to shape the panel (skin) on it; the other is to make the panel (skin) first, and then in the space around it ‘sweep foam. Thermosetting foams are made by foaming the billets first and then foaming the billets at a higher temperature. The Foam interlayer furrow can be used as aircraft rudder surface, cabin door, helicopter rotor and so on. It can also be used for other civil purposes such as sound insulation, heat insulation, shock absorption components. The rigid foam sandwich structure is mostly load-bearing: The flexible foam sandwich structure has large deformation and is suitable for shock absorption.

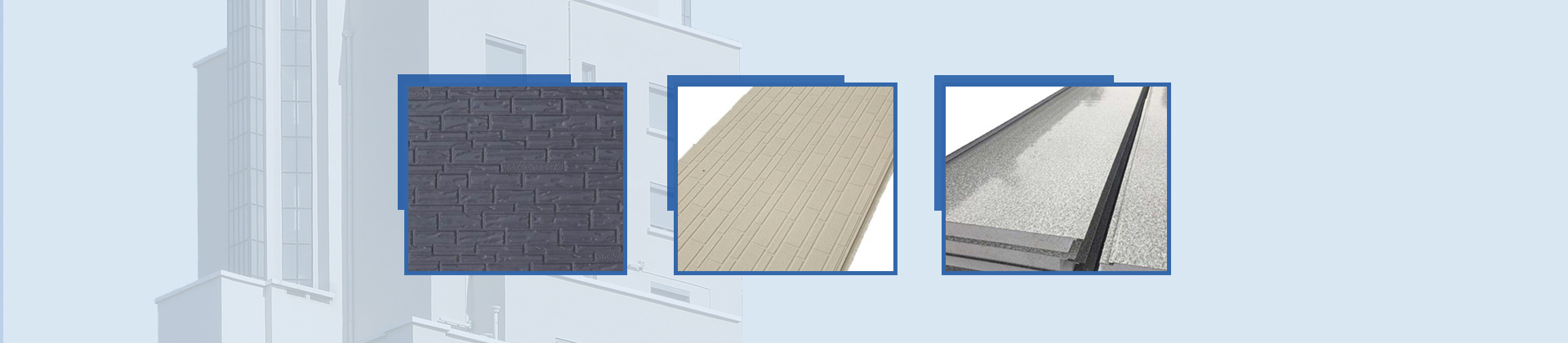

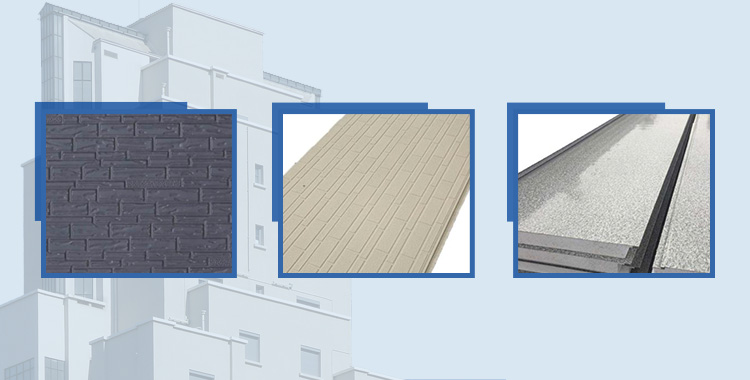

When buying insulation substances, not only to recollect its thermal conductivity but also want to do not forget its weight. if the insulation layer is just too heavy it is going to be difficult to install then growing the development expenses. the floor of the panel is embossed metallic which after baking finish and wont appear cracks, bulge. no radioactive contamination, fitness and environmental protection, it's miles an kind of environmentally friendly wall panel.right pleasant, it has solid bodily structure and chemical shape, product qualification fee can be reached 99%.it could keep ornamental effect of the external partitions for greater than 45years.