Key points of the integration of thermal insulation and decoration

Insulation decoration safety

The finished board after installation adopts a variety of installation methods to ensure the safety of the system:

1. Advanced composite materials are used to ensure that the upper and lower sides of the tempered glass are lined, and there is a firm bond between the heat insulation board and the reinforcing layer;

2. Adopting specially configured bonding mortar, its bonding strength is much higher than traditional external thermal insulation bonding mortar;

3. High-strength metal anchoring to ensure a long anchoring time for the finished plate.

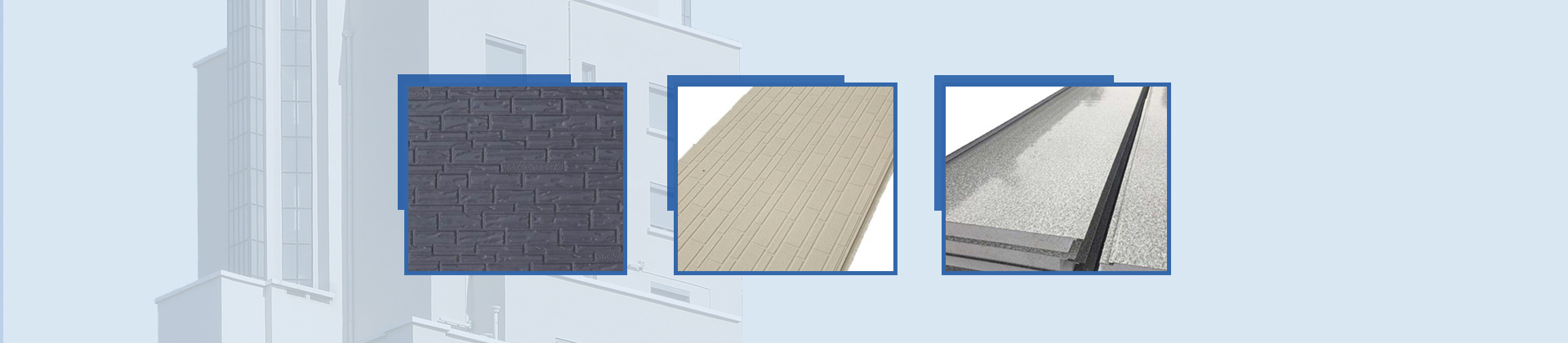

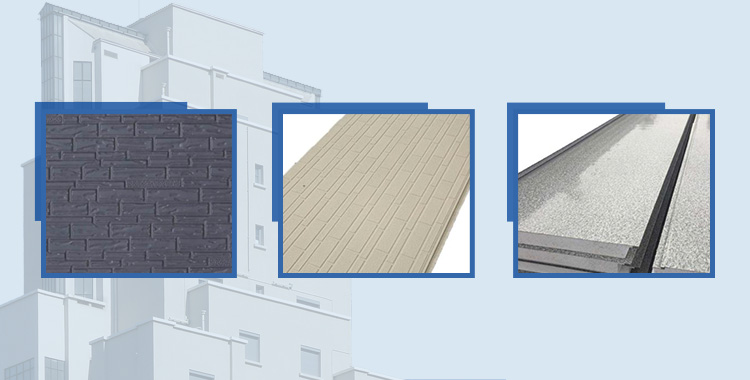

Series products.

1. Fluorocarbon metallic paint decoration series.

2. Metallic paint decorative surface series.

3. Fluorocarbon paint series.

4. Polyurethane real paint finish series.

5. Imitation stone type, imitation stone type, imitation stone type decorative surface series.

6. Different color decoration series

7. Silicone acrylic paint decoration series.

8. Simulation brick and slate paint series.

Decorative safety

1. No radiation elements, energy saving and environmental protection. Choose the polyurethane foam with the lowest thermal conductivity to meet the national building energy-saving index. The product is non-toxic, odorless, non-metallic, non-parasitic, non-leaking, non-shedding, and has a certain sound insulation effect.

2. Practical, strong durability, corrosion resistance, aging resistance, wind pressure resistance and impact resistance. As the protective layer and decorative layer of thermal insulation materials, polymer composite materials and fluorocarbon imitation stone paint have good light resistance and light resistance, and have a long service life.

3. Good availability. The exterior surface is decorated with imitation stone lacquer, with a variety of colors, which can be customized according to customer requirements.

4. The building environment is not restricted by the environment, and the disadvantages caused by different construction process factors are eliminated. Very simple installation, because the fixing method of fixing bolts is used, no basic treatment is required, and the keel-free hanging plate is directly installed, which shortens the construction period.

5. Good fire resistance, no toxic gas generated; this product uses composite materials and imitation stone paint as the substrate and surface treatment, and has good impact resistance.

6. Light weight, high hardness, not easy to break, easy to handle, used for external wall insulation, does not affect the bearing capacity of the building, and can reduce the cost in design.

7. In addition to the application of new buildings, the supporting projects for the renovation of old buildings are also simple and easy, and the application range is very wide. The updated surface decoration materials can also be made into high-end decorative wall panels such as white jade, jade, amber and so on.

Installation process

The needs of the grassroots

The unique layered structure of the thermal insulation decorative panel ensures that the thermal insulation decorative panel itself is firm and flat. Generally speaking, when installing thermal insulation decorative panels, the base layer must meet the standard of plastering, no powder, no sand, no hollowing, no peeling, flat, vertical elevation, and vertical sun angle.

Since the base wall is slightly uneven and rough, it can be leveled with a special leveler, so the insulation decorative board has low requirements on the flatness and smoothness of the base, and it is easy to handle. This is in sharp contrast to high-end coatings such as metallic paint and fluorocarbon paint, which, in order to achieve the effect of imitating aluminum plates, use more than ten procedures to process the base layer.

viscosity.

The thermal insulation decorative board adopts lightweight thermal insulation board, and its dead weight is only 8~10kg per square meter (organic thermal insulation board type), which is smaller than the overall weight of the national EPS/XPS thin plastering on-site operation system. Therefore, it only needs to be Paste it on the wall to achieve the required bonding strength.

Anchor

In this regard, an anchoring method can be used to fix one or more decorative panels of different materials on the decorative surface, and once again make one or more decorative panels tightly connected with the wall, completely eliminating delamination and peeling The phenomenon of improving its overall safety.

It provides a complete guarantee for the exterior wall decoration of high-rise buildings.

Stitching

At the installation site of the thermal insulation decorative board, a 5-10mm wide gap is reserved between the two boards. After processing, fill the mortar on the bottom of the board into the cavity, and then fill the entire seam with durable silica gel.