Fireproof Textured Decorative Foam Exterior Wall Panels

Compared with traditional materials, it has excellent heat insulation and cold resistance performance. The heating and cooling energy consumption is greatly reduced thus saving energy expenditure, cost-effective.Its unique design structure completing elimination of the "cold and heat bridge effect". Effectively avoiding indoor moisture, mildew and other phenomena. At the same time, as the panel is installed on the external wall of the building so avoiding the damages to the whole structure which caused by rain and snow weather and other natural factors.

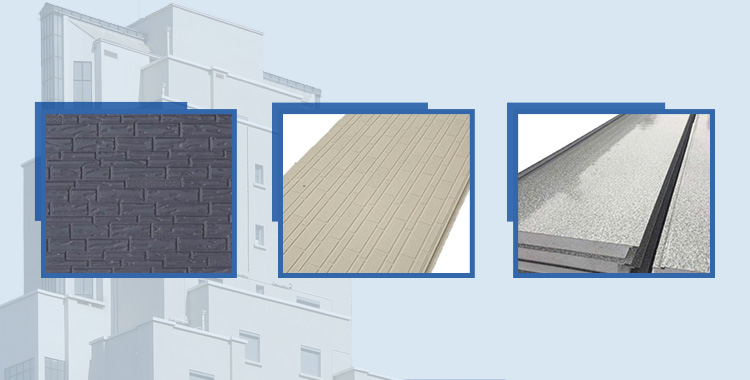

Model No.: ZT-SB

Length: Customed

Core Material: Rigid Pu Foam

Weight: 3.7kg/m²

Width: 38cm

Thickness: 16/20/25mm

Surface Material: Aluminized Galvanized Steel

Packaging: cartons

Productivity: 1000sqm per day

Brand: ZT

Transportation: Ocean

Place of Origin: China

Supply Ability: 1500000 per year

Certificate: ISO CE

HS Code: 392113900

Port: Qingdao

The advantages of PU insulated decoration wall panel:

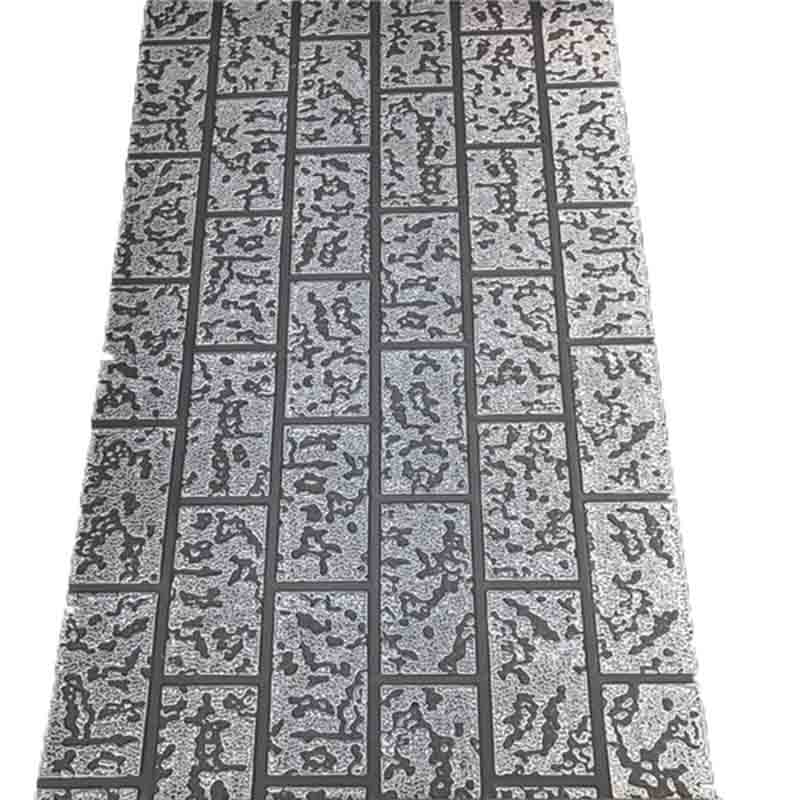

When purchasing insulation materials, not only to consider its thermal conductivity but also need to consider its weight. If the insulation layer is too heavy it will be hard to install then increasing the construction costs. The surface of the panel is embossed metal which after baking finish and wont appear cracks, bulge. No radioactive contamination, health and environmental protection, It is an kind of environmentally friendly wall panel.Good quality, it has stable physical structure and chemical structure, product qualification rate can be reached 99%.It can maintain decorative effect of the external walls for more than 45years. It is easy to clean and just need to use neutral detergent to wash.The surface material of the panel is aluminized zinc sheet which the thickness is 0.30mm.Its weather resistance, acid resistance, alkali resistance, smoke resistance after special process .Rigid polyurethane foam is the most environmentally friendly insulation materials in the world. Its insulation performance decreased only less than 3% after 25 years under high temperature testing.