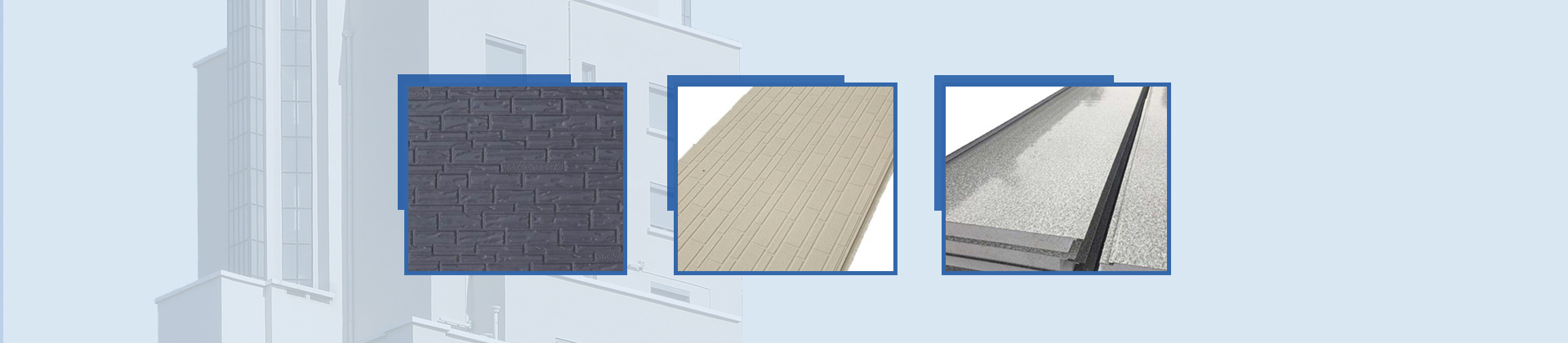

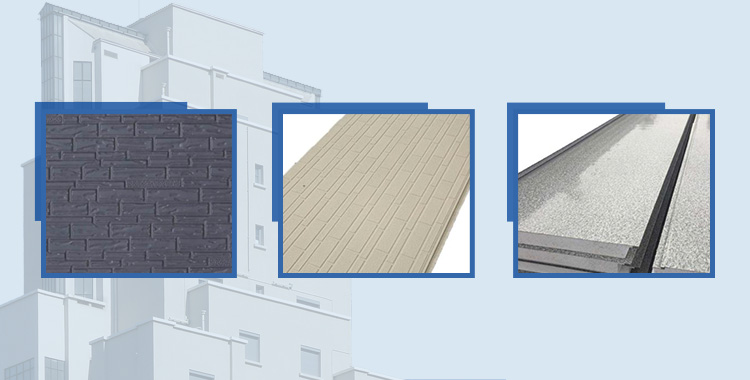

Polyurethane Sandwich Board Detailed Introduction

Polyurethane sandwich board has beautiful appearance and good overall effect. It integrates load-bearing, heat preservation, fire prevention and waterproof, and does not need to be decorated twice. It is quick and convenient to install, short construction period, good comprehensive benefit and good cost performance. At present, it has been widely used in industrial plants, logistics and storage, integrated house wall, roof envelope system and other fields.

Polyurethane sandwich board is also known as leakproof sandwich roof board, polyurethane foam insulation board, polyurethane composite board, PU board. It is a bimetallic, single metallic and non-metallic composite plate with polyurethane hard foam as an insulation layer. It is a highly efficient and energy-saving building envelope material with wide use and great potential. It is also a new energy-saving plate advocated and promoted by the Ministry of Construction of the People's Republic of China, and can be applied to various building needs:

1. Public buildings

Such as: Airport, station waiting hall or waiting hall, sports venues, theatres and auditoriums, exhibition halls and exhibition centers, museums, and other public buildings, due to the need for large space, this kind of buildings mostly use the roof structure form of grid truss or pipe truss. Therefore, higher requirements are put forward for the materials of roof panels in light weight, heat preservation and heat insulation, fire safety, waterproof, sound absorption, durability and so on.

2. Industrial plant and warehouse

The advantages of polyurethane sandwich panels, such as light weight, fast efficiency and flexible layout, have made them the preferred solution in single-storey factory buildings. For the multi-storey industrial workshop, in addition to the roof of the roof can be used sandwich panels, the external wall can also be used polyurethane sandwich panels for flexible layout, through the color coated panels to achieve the purpose of beautifying the appearance of the building. For industrial buildings requiring constant temperature and humidity, sandwich panels with better thermal performance than brick walls are used as envelope materials, which can greatly save the operating cost after completion.

3. Purification project

With the rapid development of electronic and pharmaceutical industries, the requirements for the cleanliness of the production environment are becoming higher and higher. Polyurethane sandwich board is widely used in production and working environment with clean requirements because of its surface color coated board is not easy to adhere to dust, easy to clean and few seams, so it is used as interior wall and ceiling material.

4. Composite houses

Composite houses built with polyurethane sandwich panels have a series of advantages, such as light overall weight, flexible combination, convenient and quick construction, no need for secondary decoration, easy disassembly and relocation. The characteristic of sandwich panel assembly house can be moved several times makes it widely used in temporary buildings. In addition, a large number of composite houses with sandwich panel are also used in industrial plants for various purposes.