6 Reasons to Choose Sandwich Panels

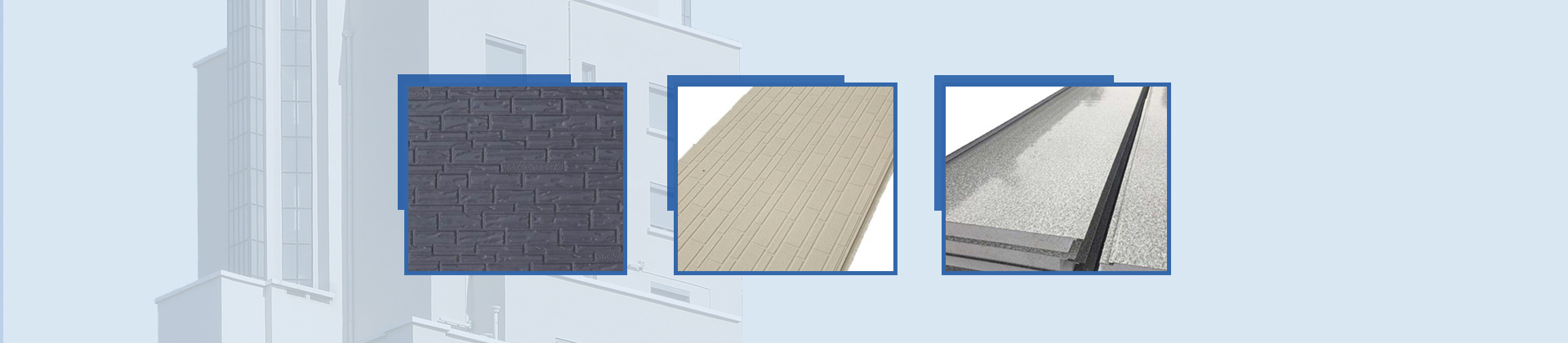

The sandwich panels range with the aid of:

Period (2 to 18 m)

Thickness (forty to 230 mm)

Center kind (eps, mineral wool, polyurethane)

Profile (smooth, micro-profile, clearline, grooved etc.)

Protecting coatings (polyester sp, sp polyester mat pearl, cesar pur 55, aluzinc), with panels also used with chrome steel cladding

Cladding colors (each external and internal)

Every panel includes numerous layers: middle with thermal insulation, metal claddings (external and internal) and coatings defensive from mechanical damage and corrosion.

For example, let’s compare two popular technologies used in warehouse building construction.

In the first case the external partitions consist of double brick walls, while in the second case they consist of sandwich panels.

By selecting the first case we have to order the following works: wall construction, thermal insulation installation and, finally, external layer installation.

By selecting sandwich panels, the construction process is far less complicated and thus quicker and, most importantly, cheaper. Panels are finished components, suitable for easy installation, e.g. to a steel structure.

Considering the present situation on the construction services market, working time plays a key role in the cost optimisation process. The quicker the structure is completed, the less we spend on construction service costs, which have increased significantly in recent years. The rapid structure completion process also translates to earlier commencement of occupancy, which improves the return on investment for business projects.